Flexibility, reliability, and adapting to the available space are the vital features that have enabled the Flex PCBs to revolutionize electronic products. They can bend and fit in any area and decrease the product weight. The reduced joints and wire connections increase the board stability. Flex PCBs are cost-effective and compatible with most types of connectors and components. These benefits make the Flex PCBs a perfect choice in several applications like consumer electronics, medical, automotive, military, aerospace, and satellite applications.

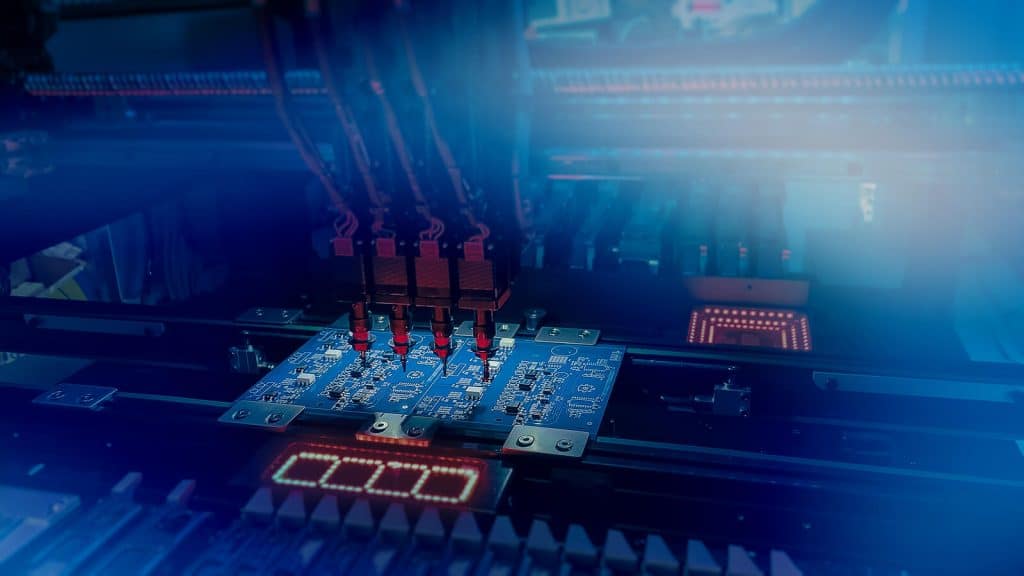

A flexible Printed Circuit (FPC) includes a flexible film and thin conductive layers establishing the electrical connections among the electronic components via soldering or conductive adhesives. Some of the common types of Flex PCB used in the industries are:

1. Single-sided FPC contains one conductor layer on a flexible dielectric film and is printed on one side. It is the simplest and most easily affordable type of Flex PCB. They are typically used in calculators, timing circuits, etc.

2. Double-sided FPC includes printing on both sides of the dielectric film and connected using plated vias. They improve circuit density and power capacity. They are generally used in converters, regulators, etc.

3. Multi-layer FPC has more than two conductive layers and is quite expensive. They are used in advanced applications like aerospace and military devices.

4. Rigid-Flex PCBs are a hybrid of rigid and flexible PCBs featuring the best qualities of both types. They offer better electrical performance and reliability.

While all these types are used in some applications, Rigid-flex PCBs are widely used and impact most electronic industries. One-third sales are generated by consumer electronics like digital cameras, cell phones, smart devices, etc. Flex PCBs are cost-effective and support fragile connections with higher reliability, and these features are best suited to bulk produce consumer gadgets.

Impact of Flex PCBs in the Healthcare sector:

Flex PCBs have tremendously impacted the healthcare sector by driving advanced diagnostic, monitoring, and wearable medical devices. They can include several components like sensors, tiny cameras, batteries, etc., within a compact package resulting in miniature implantable devices. Various activity trackers for health monitoring are available in the market today.

The possibility of packing a flex PCB in unconventional shapes is an excellent advantage in manufacturing sophisticated monitoring and diagnostic apparatus for the healthcare sector. Recently, they are used in medicine delivery systems also. Smart wristwatches are designed using it to monitor the circulatory and respiratory parameters of a patient. The data can further be shared with the corresponding health professional for evaluation.

Because they are durable, lightweight, and resistant to heat and chemicals, they are best suited for the manufacturing of medical devices like Pacemakers, Cochlear implants, handheld monitors, etc.

Revolution in the Automotive industry:

The automotive sector has gone through many advancements, and the customers are currently looking for high-end vehicles. Multiple mechanical and electrical components are involved in designing an automotive PCB. Handling massive cable connections and enduring high temperatures and vibration are some of the challenges in this domain. Rigid-Flex PCBs can reduce potential electrical failures by minimizing the connectors and solder joints. Performance of electronic control systems in the automotive will proportionally improve.

The decreased assembly steps like cable soldering, connector assembly, etc. help in a cost-effective manufacturing process. Rigid-flex circuits can be efficiently packed in smaller spaces, simplifying the maintenance of the electronic consoles. For example, the thermal performance and compact space allotments of flex PCB allow adding features like GPS navigation and rear-view camera displays to the dashboard.

Flex PCBs in Military and Aerospace applications:

To operate consistently in a harsh environment, Flex and Rigid-flex PCBs are used in military and aerospace applications for a long time. They act as the perfect packaging medium for a high-shock and vibration environment. The critical requirements like dependability and robustness of the military-grade machines (e.g., unmanned vehicles, military robots, etc.) are achieved using them. They deliver lightweight military equipment without any degradation in performance while operating in extreme conditions.

The ability to adapt to small spaces has made them an ideal choice for aerospace applications. Other features like low-weight, exceptional mechanical and electrical connection, resistance to vibrations, extreme temperature, and radiation offer an optimal solution for aerospace applications.

Flex PCBs in Satellite applications:

Several advantages of Flex PCBs are driving the global space organizations to design and develop commercial satellite products. The versatility of fitting in any size and shape, especially in a small area of the spacecraft, makes Flex PCBs the ultimate choice. It can be built in odd shapes and branch out to various connectors. It can flex thousands of times while operating without any damage to the circuit. Thin copper layers and insulating layers allow minimum bend radius, enabling them to fit in compact spaces.

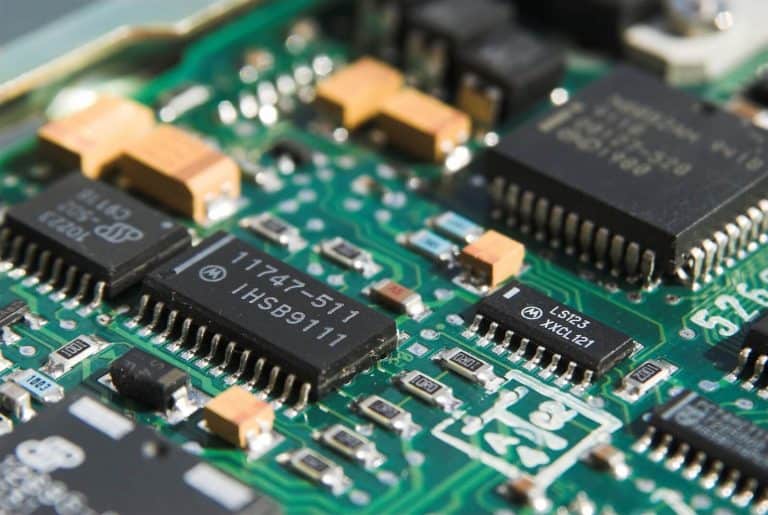

There is great progress in the performance of electronic products built using flex PCBs. Higher circuit density, reduction in size and weight, decreased circuit failures and good temperature ranges are some of the significant features promoting the usage of Flex PCBs in the Electronics industry. Though the material cost is higher and the assembly process is complex, Flex PCBs offer unique benefits that cannot be ignored.

Flex PCBs are impacting many industries like telecommunication, e-commerce, and other business applications. With the optimized heat-resistance quality, they are capturing the latest range of thin LED products. The PCB manufacturing process is also undergoing many upgrades to catch up with technological innovations. New substrate materials and new technologies are together driving future innovations.

The ultra-thin and high-density features of Flex PCBs are increasing their demand in numerous electronic applications. The future development is focused on the aspects like higher stable working temperature, component embedment, high data processing speed, lighter PCB structure, and many more. With these newly added features, it would be interesting to see the scale of impact of Flex PCBs in various industries.