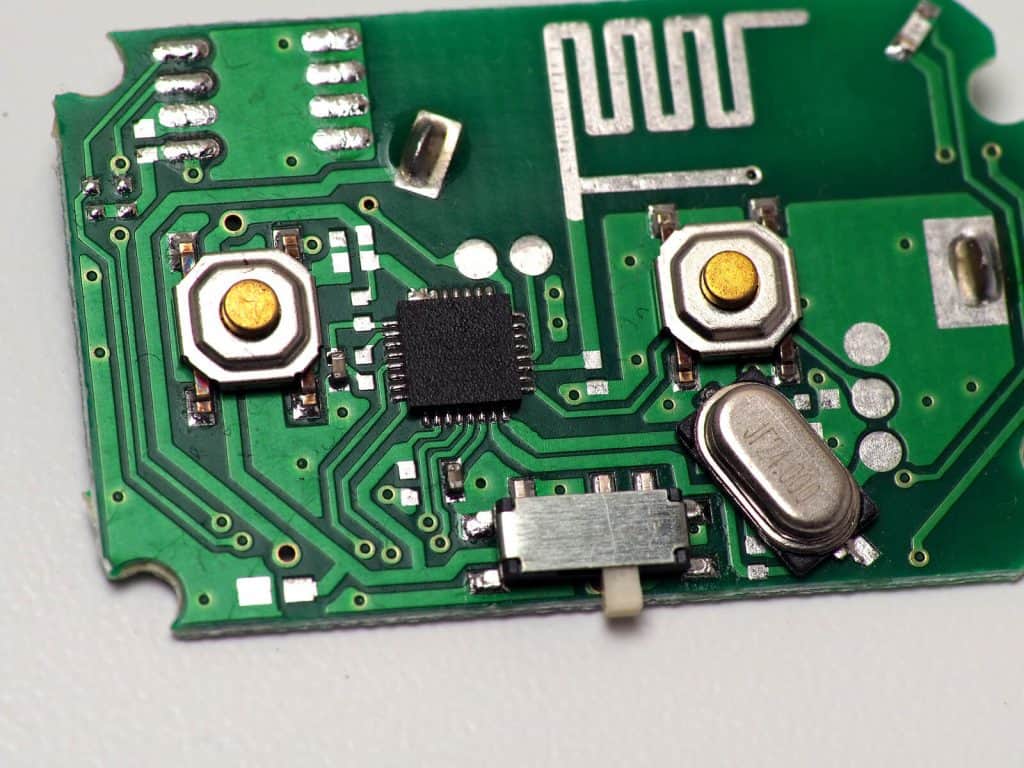

Electronic business is growing drastically along with the progress in cutting edge technologies worldwide. Any new electronic product is built with a PCB as its backbone. Electronic and electrical components are mounted on a circuit board and connected via traces to create a functional design. This PCB Assembly (PCBA) constitutes more than half of the manufacturing cost of any electronic product. Hence, it is acknowledged as the Heart of Electronics Business all over the globe.

Table of Contents

TogglePCBs are used in consumer electronic goods, medical equipment, automotive, robotics, and many more applications. The demand for such electronic devices is continuously increasing to ease our livelihood. This suggests how the electronic business is thriving, and so does the PCB assembly requirements.

Any new electronic product calls for a multi-stage development cycle. In the initial prototype stage, the PCBA will act as a test platform to verify the critical functions of the new product. There may be multiple test points provided for easy debug and analysis. Once the product’s core features are verified, the PCB assembly will be tested for full features in real environmental conditions. At this stage, the PCBA will be tested for bulk production by following ‘Design for Manufacturability’ (DFM) checklists. The product is checked for user safety, efficient functionality, and robust manufacturability at the final stage. Hence, PCBs serve as the best-optimized tools for the manufacturing of electronic products.

PCBs can be seen in simple electronic devices to complex medical, automotive, or space equipment. They have many advantages in product manufacturing like improved operational efficiency, higher productivity with low material cost, compact size, etc. Many PCB Assembly providers offer quality services for PCB fabrication and assembly and testing and debug support.

PCBs serve intricate functionalities of a wide range of electronic products by ensuring high-quality data and signal transmissions. Consumer products demand PCBs capable of dense packaging with digital and analog circuitry in compact sizes. In contrast, Industrial products require rugged PCBs that can comply with different requirements like safety and reliability. Fulfilling all these diverse requirements, PCB Assemblies have become the heart of the Electronics World.

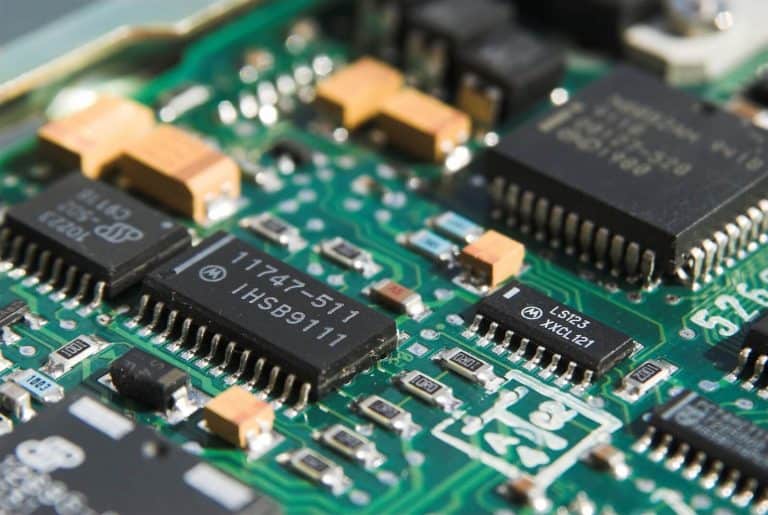

With growing technology, PCB manufacturing is also evolving. Earlier, component assembling was done easily manually, but now the tiny parts of PCBs are assembled by machinery to improve precision and efficiency. Also, the varied category of PCBs like single layer to multi-layer, rigid to flexible PCBs is all developed to meet the requirements of various domains of the electronics businesses.

We shall briefly discuss some of the electronic applications, highlighting the significance of PCB assembly in each one.

Consumer Electronics:

This includes various products ranging from tech gadgets (smartphones, laptops) to home appliances (latest refrigerators, dishwashers). These products operate mainly due to the electronic components and circuit boards present within, designed to provide consistent outputs. With the continuous demand for such consumer products, it is evident that the PCB assembly has captured the Electronics market worldwide.

Medical Equipment:

The health care industry has improved the human life span to a great extent with its path-breaking research and development in medical science. This is proficiently supported by the high-tech medical equipment used for diagnostics, monitoring, and treatment purposes. PCB assemblies are the backbone of all such high-end equipment specialized to handle the set medical constraints. High-Density Interconnect (HDI) PCBs and Flexible PCBs are some of the most common types of PCBs used in medical equipment. Small size PCBs are used in implant devices.

Industrial Applications:

PCB assemblies are used in industrial applications with production lines or manufacturing units that survive a harsh environmental setup. They can enable automation of the production process and save operational costs to a great extent. Thick copper PCBs can provide robust solutions in industrial applications that involve vibrating machinery or rough treatment.

PCB assemblies are used in Industrial Power equipment like inverters and generators.

Telecom networks are heavily dependent on switchboards that essentially include chassis and multiple complex PCB assemblies.

Automotive Applications:

Latest vehicles feature a range of sophisticated applications that include sensors, navigation devices, control systems, etc. The use of PCB assembly is a must to handle these new requirements of the automotive industry. Boards with Flexible PCBs are an ideal choice in such requirements, which can withstand high vibrations also. The audio and video devices are part of the advanced dashboards in all the latest cars available in the market. This again indicates the demand and usage of PCB assemblies in the automotive business.

Safety and Security Equipment:

PCB assemblies are part of the security cameras and smoke detectors used for the safety and security of housing communities or business organizations worldwide. Reliable and small size PCB assemblies are used in these applications.

Military and Defense Applications:

Control systems and communication equipment used for military and defense purposes are mainly based on high precision PCB assemblies. There is a stringent requirement to operate in harsh conditions. So, some of the most advanced PCB designs are used in these applications.

Aerospace Applications:

One of the most complex and advanced electronic applications is found in the Aerospace domain. The high-end testing, monitoring, and communication equipment used in Aerospace applications are made out of the best PCB assemblies in the market. This application’s associated turbulence and high-pressure environment are challenges met by a durable and robust PCB assembly.

The above discussion has clearly brought out the significance of PCB assembly in the electronics world. It is the optimal way of manufacturing any electronic product, right from consumer electronics to aerospace applications. Thus, PCBA provides consistent performance and ensures to rule the electronic business worldwide.