Artificial intelligence (AI) in supply chain management is no longer about a future promise. There may be some variations in adoption across industries, but the technology is having a significant impact on how companies operate today. That’s the broad conclusion from KPMG’s 2020 Living in an AI World study. But is it possible to quantify that impact across specific use cases or business functions, like the value of AI in supply chain management (SCM), for instance?

Table of Contents

ToggleA McKinsey global survey sets out to answer that question by studying the cost and revenue impact of AI adoption across 33 use cases and eight business functions – including the impact of AI in supply chain management. Overall, a majority (63%) of these early AI adopters have seen revenue increases, and around 44% report cost savings. High performers are also three to four times more likely to report shifts of more than ten percent in terms of the same metrics.

(Image source: McKinsey)

Turning specifically to the focus of this article, the study ranked the impact of AI in supply chain management second and third across all eight business functions studied in terms of share of respondents indicating the potential for cost decrease and revenue increase. Overall, 63% and 61% of respondents indicated that they were able to achieve revenue bumps and cost reductions, respectively. Within SCM, sales and demand forecasting, spend analytics, and network optimization were the most likely use cases for driving these shifts.

The McKinsey study provides a broad overview of the potential impact of AI in supply chain management. However, it does look like it will take some time before real-world adoption scales up to reflect that potential.

Adoption of AI in Supply Chain Management

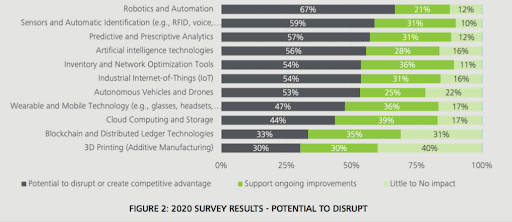

Currently, a mere 12% of businesses are deploying AI in supply chain management, as per a recent report from MHI and Deloitte. Compared to the previous year’s edition of the same study, AI has even dropped a rank in terms of disruptive potential, relegated to the fourth position by an increasing emphasis on sensors and automatic identification.

(Image source: 2019 MHI Annual Industry Report – mhi.org)

(Image source: 2020 MHI Annual Industry Report – mhi.org)

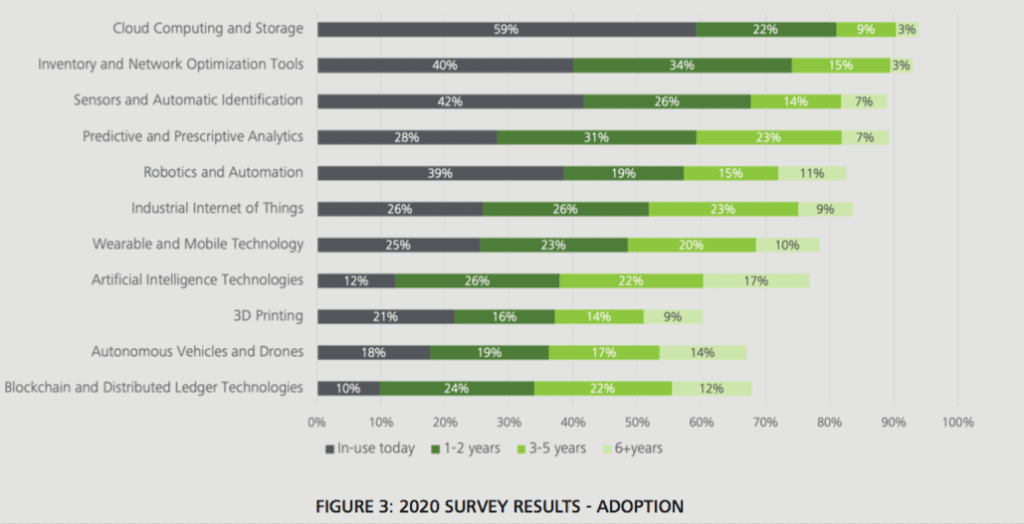

Even in terms of adoption priorities, AI is currently in the eighth position behind even complementary technologies such as IoT, robotics, and prescriptive analytics. The good news is that nearly one-quarter of respondents to the study expect to have deployed AI over the next two years.

(Image source: 2020 MHI Annual Industry Report – mhi.org)

But, as the authors noted in their 2019 report, AI “depends on many of the survey technologies as a foundation.” As such, there could be a lot of overlap in capabilities between some of these discrete clusters – and therefore, a huge leap in the potential impact of AI in supply chain management. The other point to consider is that companies need to build the digital infrastructure required to deploy technologies like AI and machine learning (ML). This point has been analyzed further in a European survey on the digital readiness of corporate supply chains.

Defining Digital Readiness of Supply Chains

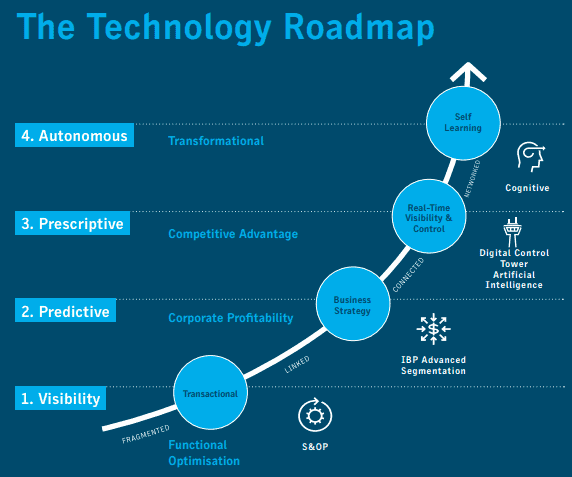

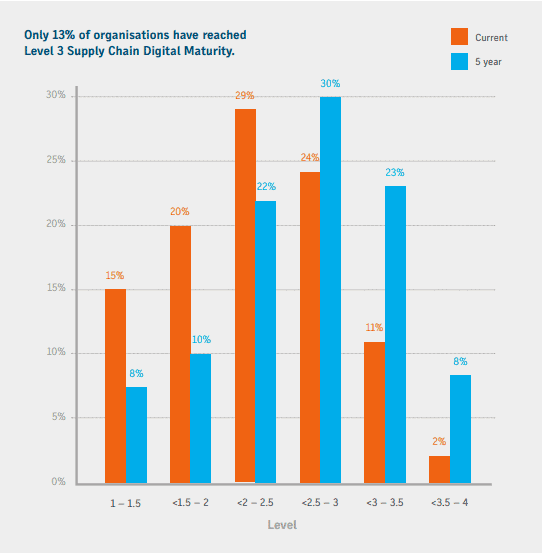

Last year, supply chain specialist JDA (now Blue Yonder), in association with the Warwick Manufacturing Group (WMG), published a Supply Chain Digital Readiness study that defined digital readiness across four key levels. The researchers worked with 180 major European manufacturing companies to understand how close they were to achieving a fully digital supply chain.

(Image source: JDA/WMG)

The findings revealed that over a third (35%) of the companies that participated in the study were still at level one. i.e., end-to-end data visibility still remained the primary objective, supply chain processes continued to be backed by basic ERP systems, and they relied on simple analytics tools like spreadsheets, predominantly for reporting.

Just over half (52%) qualified for level two readiness – i.e., there was limited deployment of specialist SCM tools, a degree of process automation, and the use of analytics tools to drive cost optimization efforts.

(Image source: JDA/WMG)

Level three remains an exclusive club with just 13% qualifying for access based on their capabilities for dynamic end-to-end supply chain optimization, use of advanced analytics including ML/AI, and real-time visibility across the IoT and supply chain ecosystem. Level three readiness, however, is projected to more than double (31%) by 2023. Over the next five years, just under 10% of companies are expected to acquire level four self-learning autonomous capabilities.

AI in supply chain management is a market that is estimated to grow at a CAGR of 45.3% to reach $21.8 billion by 2027. However, much of that growth will be contingent on organizations’ ability to ensure that their supply chains are digitally ready. For instance, Gartner has warned that 80% of supply chain blockchain initiatives will remain stuck in proof-of-concept (POC) or pilot stages unless companies focus on digitizing their supply chains. It is a similar situation for AI in supply chain management, as the progress of deployment will depend entirely on the success of digital transformation initiatives focused on supply chains.

Digital supply chains, with end-to-end visibility, AI/ML-driven intelligence, real-time decisioning capabilities, and a significant degree of autonomy, are more an inevitability than an option. Most SCM leaders acknowledge this new reality, with a huge majority (80%) expecting digital supply chains to become the predominant model over the next five years.

For companies that are willing to invest the resources to drive the necessary digitization, technologies like ML and AI have the potential to transform almost every aspect of supply chain management to enhance growth, profitability, customer experience, and competitive advantage.

AI/ML Applications in Supply Chain Management

AI and ML have a range of applications across the SCM value chain, including in supply chain planning, warehouse management, fleet management, risk management, inventory management, planning and logistics, and communications. Here’s a brief look at how these technologies can enhance the efficiency, productivity, and value of each of these applications.

AI/ML in Transportation and Fleet Management

The global TMS (Transportation Management Systems) market is expected to grow at a CAGR of 14.5% and almost double over the next five years, from USD 2.5 billion in 2019 to USD 4.3 billion by 2025. The development arc of these systems mirrors the exponential growth in data sources, such as IoT sensors, actuators, RFID, GPS, and barcodes. As a result, modern transportation management systems need to do more than record time and place of shipments. Today, a digital TMS needs to facilitate smart functionalities like dynamic routing and automation across the transportation lifecycle to enable businesses to optimize transportation performance in real-time. Dealing with the volume and the diversity of this new data will be next to impossible without embedded ML and AI.An ML/AI-enabled intelligent TMS can automate almost every process across the transportation value chain, starting with load tendering. In fact, smart systems that combine advanced analytics and embedded intelligence are able to autonomously handle 25% or more of load tendering and automate related activities, including booking, approval, routing, and alerts. These solutions allow operators to dynamically switch not just between optimal routes, based on weather, traffic, etc., but also between cost-effective greener alternatives to manage transportation risks and costs while enhancing productivity, efficiency, and performance.

Technologies like AI and ML are facilitating a new generation of transportation management solutions that continuously learn by comparing inputs with outcomes. They also introduce innovative capabilities such as real-time fleet tracking, improved vehicle utilization, and more cost-effective and proactive approaches to fleet maintenance. Most important of all, intelligent TMS allows companies to come up with the best transportation and logistics strategies that perfectly balance the competing priorities of shippers, drivers and fleets without compromising service levels.

AI/ML in Warehouse Management

A conventional warehouse management system (WMS) did not traditionally incorporate any form of advanced intelligence beyond basic descriptive analytics. However, WMS capabilities are slowly but surely evolving to support the intelligent warehouse of the future. In fact, Gartner estimates that by 2024, at least half of all WMS offerings will include embedded machine learning capabilities. In fact, the analyst’s Magic Quadrant research methodology for the WMS market now takes into consideration advanced capabilities such as predictive or prescriptive analytics, ML and AI, and integration with emerging material handling automation techniques such as robotics.

AI and ML technologies are ideally suited for the increasingly complex and dynamic nature of the modern warehouse. The functionalities of an intelligent WMS extend far beyond basic inventory management to optimize all core warehouse management processes. For instance, once products are scanned at the warehouse entrance, algorithms can autonomously determine optimal stocking positions and identify the most efficient routes for workers. AI/ML can also help warehouse managers understand the impact that different attributes have on task completion and order processing times in order to make workflows more productive and efficient. Intelligent real-time tracking of all warehouse processes and workflows provides warehouse leaders with the information required to transform warehouse management.

AI techniques like neural networks and reinforcement learning are also helping warehouse robots learn how to deal with the complexity and diversity of these dynamic environments. In short, intelligent warehouse management systems are becoming the smart hub of digital warehouse operations, with data and decisioning flowing seamlessly across processes and workflows.

AI/ML in Supply Chain Planning

Digital supply chain planning (SCP) is critical to the success of digital supply chains. In a 2019 research note on supply chain planning, Gartner described a progressive model that enables companies to enhance the quality and timeliness of their planning initiatives while ensuring that their technology initiatives were aligned with the digital maturity of their supply chain processes.

As per the Gartner model, SCP in stage 1 maturity companies still involved a high degree of manual planning with basic tools like spreadsheets and models powered by low-quality data.

In stage 2, companies still have to deal with poor quality data and a discrete planning process involving multiple models aligned with different functions of the supply chain. However, there is already a big opportunity for companies to leverage the power of algorithmic tools and techniques to achieve significant improvements, even in a function-level planning process. For instance, ML can be used to self-correct master data. It can also be combined with functional planning automation to improve the quality of planning models and automate predictions in the planning process.

By the time we get to stage 5 maturity, the opportunity for companies to transition to a fully algorithmic SCP paradigm that completely transforms their approach to supply chain planning emerges. Here, the SCP process makes extensive use of multiple data types and sources with the flexibility to add new datasets at will. The business can also successfully create a fully evolved digital supply chain twin – a near-real-time digital representation of the physical supply chain that can be used to simulate interactions and relationships. There is also a high degree of prediction and prescription automation, function-level planning has evolved into an end-to-end process, with up to 95% of planning decisions being done autonomously, and supply chain planners are now more involved with managing algorithms and datasets.

AI/ML in Procurement

According to IDC’s latest supply chain predictions, at least half of all large manufacturers will automate supplier and spend data analysis by the end of the year to achieve a 15% gain in procurement productivity. In recent years, procurement has gradually shifted from being considered a tactical and transactional activity to a more strategic position within SCM as well as the business. One indicator of this increasing importance is the growing range of AI/ML-based solutions available today to address almost every aspect of the procurement function.

Today, sourcing bots can apply ML to understand and automate a company’s sourcing process, and even integrate with external systems to trigger events based on a range of variables. Contract analytics platforms automate discovery and onboarding, use Natural Language Processing to identify policies, and locate specific data points using a latent semantic indexing (LSI) engine. Intelligent supplier information management systems offer innovative ways to unify supplier data and extract valuable insights. Supplier risk management solutions use AI to analyze and identify gaps in a company’s supply and recommend specific actions to reduce risk exposure. Machine learning is accelerating accounts payable workflows, automating fraud detection, and ensuring compliance. AI-powered spend analysis solutions automate data extraction, spend classification and vendor matching and offer advanced spend analytics to improve performance, supplier relationships, and profitability. And AI-powered chatbots are streamlining procurement communications with conversational interfaces that enable frictionless interactions between procurement and supplier systems.

These are just a few examples of the impact of AI in supply chain management. As these technologies continue to evolve, we are getting closer to the next generation of data-driven, self-learning, and truly autonomous cognitive supply chains.

Final Thoughts

The current COVID-19 pandemic has exposed vulnerabilities in almost every company’s supply chain, with 94% of Fortune 1000 companies experiencing supply chain disruption and a consequent downgrade in their growth outlook. This has been a risk event that practically no supply chain risk management contingency plan has accounted for. According to some, this may well be the black swan event that triggers a large-scale comprehensive transformation of conventional supply chain models. The capabilities and technologies required to drive effective supply chain transformation are readily available. Technologies like ML and AI in supply chain management have the potential to deliver data-driven, intelligent supply chains that, apart from enabling real-time end-to-end visibility, cognitive capabilities, and autonomous decisioning, can also help companies manage atypical, world-altering risks.

Summary:

Impact of AI in Supply Chain Management

A McKinsey study ranked the impact of AI in supply chain management second and third across all eight business functions studied in terms of share of respondents indicating the potential for cost decrease and revenue increase. Overall, 63% and 61% of respondents indicated that they were able to achieve revenue bumps and cost reductions, respectively. Within SCM, sales and demand forecasting, spend analytics, and network optimization were the most likely use cases for driving these shifts. Currently, a mere 12% of businesses are deploying AI in supply chain management, as per a recent report from MHI and Deloitte. Even in terms of adoption priorities, AI is currently in the eighth position behind even complementary technologies such as IoT, robotics, and prescriptive analytics. AI and ML have a range of applications across the SCM value chain, including in supply chain planning, warehouse management, fleet management, risk management, inventory management, planning and logistics, and communications. Here’s a brief look at how these technologies can enhance the efficiency, productivity, and value of each of these applications. Technologies like AI and ML are facilitating a new generation of transportation management solutions that continuously learn by comparing inputs with outcomes. They also introduce innovative capabilities such as real-time fleet tracking, improved vehicle utilization, and more cost-effective and proactive approaches to fleet maintenance. Digital supply chain planning (SCP) is critical to the success of digital supply chains. In a 2019 research note on supply chain planning, Gartner described a progressive model that enables companies to enhance the quality and timeliness of their planning initiatives while ensuring that their technology initiatives were aligned with the digital maturity of their supply chain processes.